We offered repairing service, is the most cost effective way of dealing with failed commercial turbos. The popular reason of turbo failures.

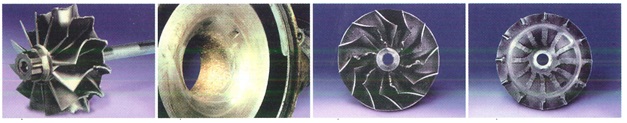

- Foreign objects passing compressor or turbine

1) Damaged turbine wheel inlet edges

2) Damage in the compressor housing inlet

3) Damage inlet edges

4) Ground Blades

- Bad oil (contaminated, wrong specification)

1) Wear on the wedge-shaped surfaces of the thrust bearing

2) Scores over the circumference of the radial bearing

3) Heatshield with carbon deposit - Overspeeding and /or overheating (often due to manipulations of the engine or the turbo)

- Turbo repairs not according to manufacturer’s specifications and / or using copy parts

- Others repairing service are fuel system, air system, starter, alternator & Speedometer.